Shelf life is generally indefinite, but use is recommended within 2 years.

Read MoreAs with any cultureware, optimal seeding density on ANFS can vary according to cell type and the purpose of the experiment. However, we recommend researchers use exactly the same cell density that they use for normal 35mm dishes, 6-well dishes and so on. Protocol information is provided on the ANFS product pages.

Read MoreNo, ANFS is already gamma sterilized and plasma treated to promoted cellular adhesion. However, researchers may choose to deposit additional surface treatments depending on their exact cell type. Fibronectin, collagen, and PLL are all common surface treatment choices.

Read MoreIdeally, no if you follow the protocol provided. However, there is a possibility that cells can attach on to plastic plate bottom if you don’t follow the protocol.

Read MoreYes. The working volume is 3 mL. Also, amount and duration for cell media change should be the same as with normal 6-well or single-well culture.

Read MoreThe plate bottom is parallel to the nanosurface. However, there will be no problem seeding the cells on the surface if the protocols we recommend are followed.

Read MoreThis dimension is about 0.7 mm.

Read MoreYes, we recommend that our customers seed cells using the same density that they do on conventional 6-well plates.

Read MoreWe recommend coating the surface with the extracellular matrix protein you typically use in your cell culture workflow (collagen, fibronectin, gelatin, Matrigel, etc.). We also have a suggested concentration in our manual for protein coating of our substrates using some of these proteins. Before starting your experiments, make sure to check our manuals where you can find the details of the protocols for each protein coating.

Read MoreAll of our cultureware (except the 12 and 25 mm coverglass and our Cytostretcher chambers) are TC-treated and ready for use. That includes the 6-well, 24-well, 96-well, 384-well plates as well as the 35 mm dish cultureware formats.

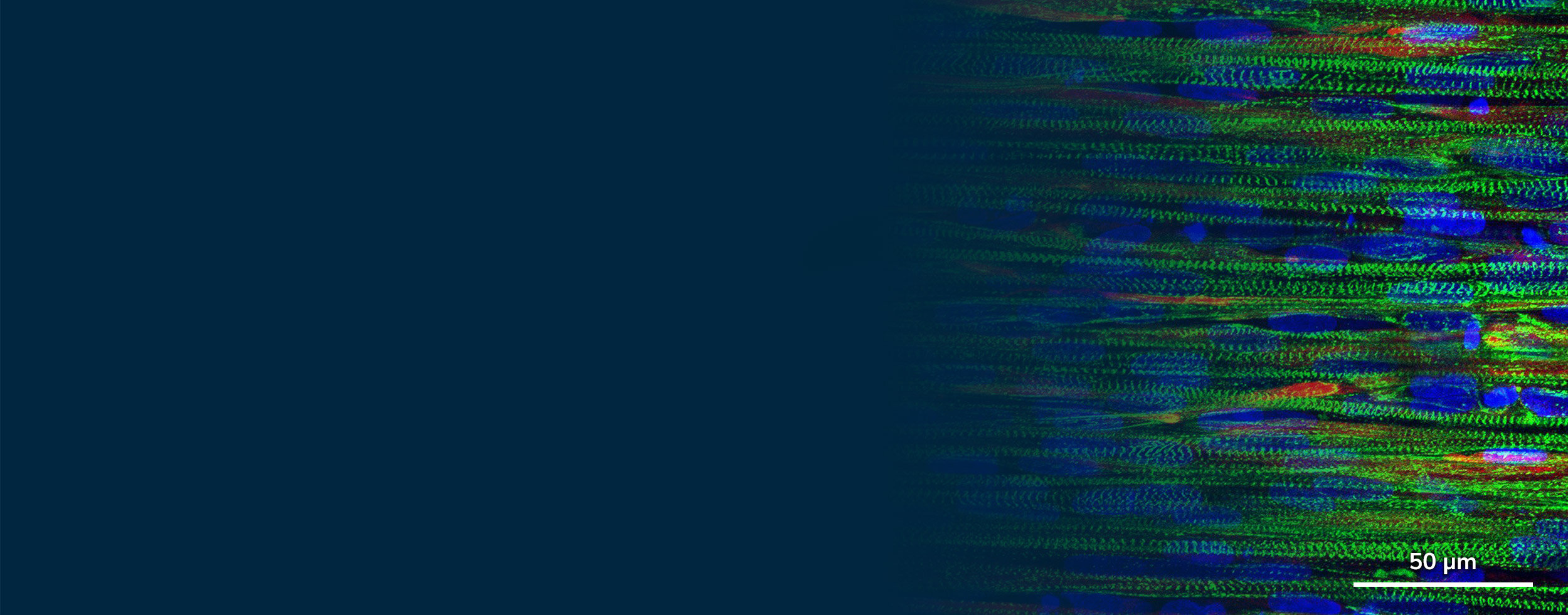

Read MoreOur coverglasses come in two different formats: (1) flat and (2) NanoSurface substrates. Generally speaking, both formats have a polymer substrate that is softer compared to conventional coverglass. As a result, the softer coverglasses are more representative of the microenvironment of tissue with respect to the mechanical properties of the substrate. The NanoSurface substrate is featured with submicron grooves with the feature size comparable to that of collagen microenvironment in body. The pattern is also optimized to be in the size of the focal adhesion of cells and facilitate the alignment of adherent cells. Our customers usually use flat substrates either for their improved mechanical properties (softer substrate) or as a control sample for nanopatterned topography to show the differences in the functionality of aligned and non-aligned tissue. The patterned feature is specifically very useful for mimicking the microenvironment of many cell lines (such as pluripotent stem cells, cardiomyocytes, neurons, vascular muscle, epithelial, endothelial, mesenchymal stem cells, cancer cells and many other cell types) in vitro.

Read MoreThe substrate thickness (glass plus polymer coating) is specified at 160 - 190 microns (0.16 - 0.19 mm). This is the same thickness specification as a No. 1.5 coverglass. The polymer has an index of refraction comparable to that of glass and thus, is optically clear.

Read More